Milestones in our development

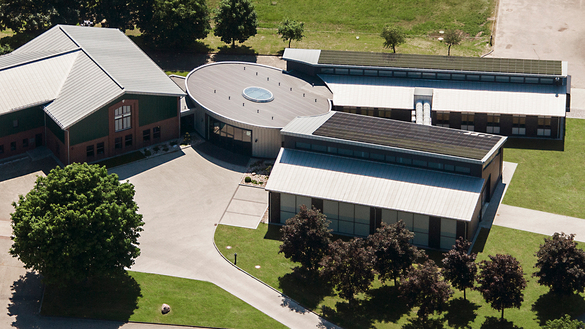

H. Wilhelm Schaumann bought Gut Hülsenberg in 1953 in order to be able to intensify practice-oriented research trials. Gut Hülsenberg was a typical value-adding operation with relatively poor soils and a high livestock density and therefore offered ideal conditions for the development of effective feed concepts. Over several decades, the estate was gradually developed into an internationally renowned research and communication centre.

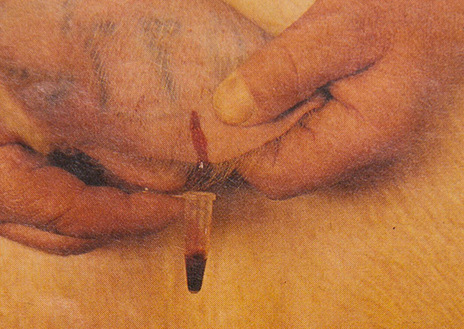

Development of the CK test

Development of the CK (creatine kinase) test for measuring stress resistance in pigs.

Deep-freezing method for boar sperm

Development of a deep-freezing method for boar sperm at the AI station on Gut Hülsenberg.

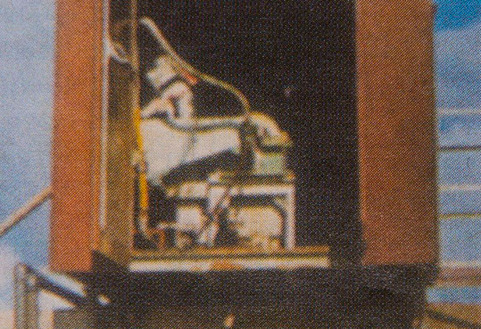

Method of processing liquid manure

Trials on Gut Hülsenberg of an environmentally friendly, effective method of processing liquid manure.

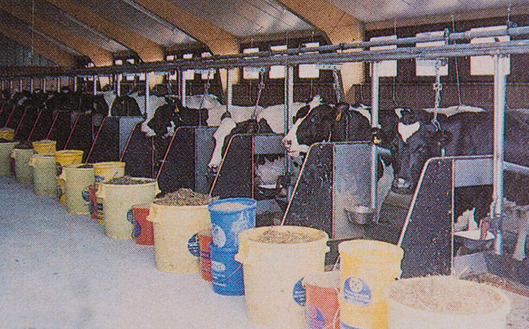

New housing system for dairy cows

Completion of a new experimental housing system for dairy cows on Gut Hülsenberg.

Relocation of ISF, New calf barn and liquid manure biogas plant

Research and development activities on the estate have intensified even further since ISF Schaumann Research relocated to Gut Hülsenberg and extensive modernisation works were completed.

New calf barn for 100 calves in three separate sections: single boxes, a deep-litter section and a slatted section with cubicles.

Commissioning of the 75 kW liquid manure biogas plant for the exclusive fermentation of cattle manure.